CSV Order Upload Instructions

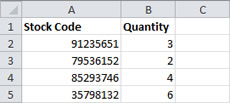

1 . Create Your CSV File

Your file must contain two columns:

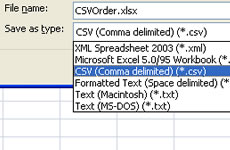

2 . Save the file as a CSV file as shown below

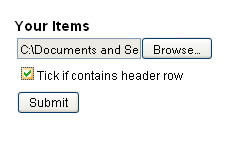

3 . Browse to the file

4 . Header Row

If you have a header row such as the example in step 1 then tick the box as shown below.

5 . Submit the file

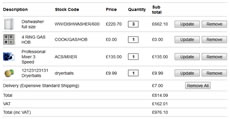

6 . Added to Basket

The products will now be added to the cart. Any items that are out of stock or with low stock will give you a message above the cart.